PRODUCTS > BALL BEARINGS

BALL BEARINGS

SINGLE • DOUBLE • OPEN • SEALED • SHIELDED • THRUST • SNAP RING

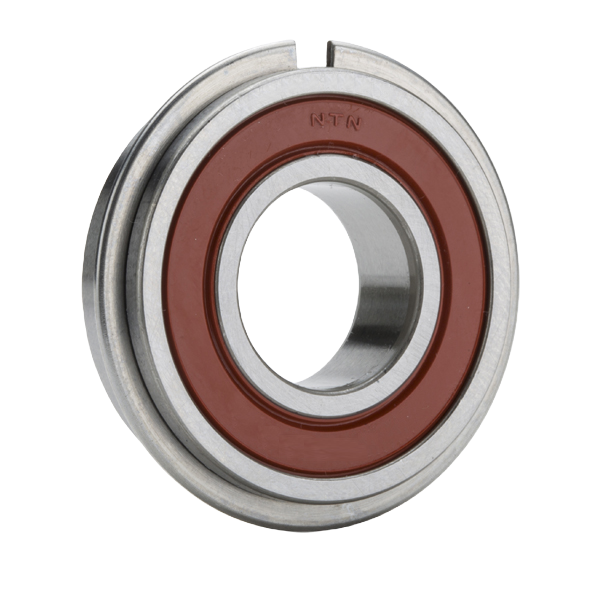

SNAP RING

Description

Snap rings, also known as retaining rings or circlips, are versatile fasteners designed for axial retention of components on a shaft or within a bore. Snap rings consist of a continuous or split circular metal band with open ends, allowing them to be installed into machines grooves on a shaft or within a housing. The snap ring's spring-like properties enable it to securely hold components in place, preventing axial movement.

Thrust Ball Bearings

Description

A thrust bearing is a specific type of rotary bearing, but like all bearings they rotate between parts. They are designed to achieve high thrust capacity with low friction and continuous roller movement. Thrust bearings range anywhere from 2.0mm to 340mm interior diameter. To learn more about thrust bearings and all other bearings we have to offer, contact us today!

OPEN

Description

These bearings consist of an inner and outer ring, with a set of steel balls positioned between them. The "open" designation means that the bearing lacks seals or shields, exposing the rolling elements to the external environment. This configuration allows for easy accessibility and lubrication. Open ball bearings are commonly employed in applications where high speeds, precision, and load-carrying capacity are crucial, such as in industrial machinery, automotive components, and various mechanical systems.

METAL SHIELDED

Description

These bearings consist of inner and outer rings with a set of steel balls sandwiched between them. What sets them apart is the presence of metal shields, which act as protective covers over the rolling elements. The shields are typically made of metal, providing a barrier against contaminants like dust and debris.

RUBBER SEALED

Description

These bearings consist of inner and outer rings with steel balls in between, and what distinguishes them is the inclusion or rubber seals. These seals, often made of synthetic rubber, form a protective barrier around the rolling elements, shielding them from dust, dirt, and moisture. The rubber seals provide an effective defense against external elements, extending the bearing's lifespan and reducing the need for frequent maintenance.

DOUBLE ROW

Description

These bearings feature two rows of steel balls held in place between inner and outer rings. The double-row design distributes the load more evenly across the rolling elements, enhancing the bearing's capacity to handle both radial and axial forces simultaneously. This configuration is particularly advantageous in applications where there are varying types of loads or moments.